The Bill of Materials (BOM) is crucial in manufacturing, detailing everything from raw materials to packaging. Traditional BOM management often suffers from inefficiencies and errors, but online BOM management software revolutionizes this process by offering centralized data storage, real-time updates, and improved collaboration.

The Bill of Materials (BOM) is the backbone of any manufacturing process, detailing everything from raw materials to sub-assemblies and even the packaging used. However, managing the intricate web of components and materials required for production is no mean feat.

As crucial as it is, BOM management often gets bogged down by inefficiencies, errors, and miscommunications, especially when handled manually or through outdated systems.

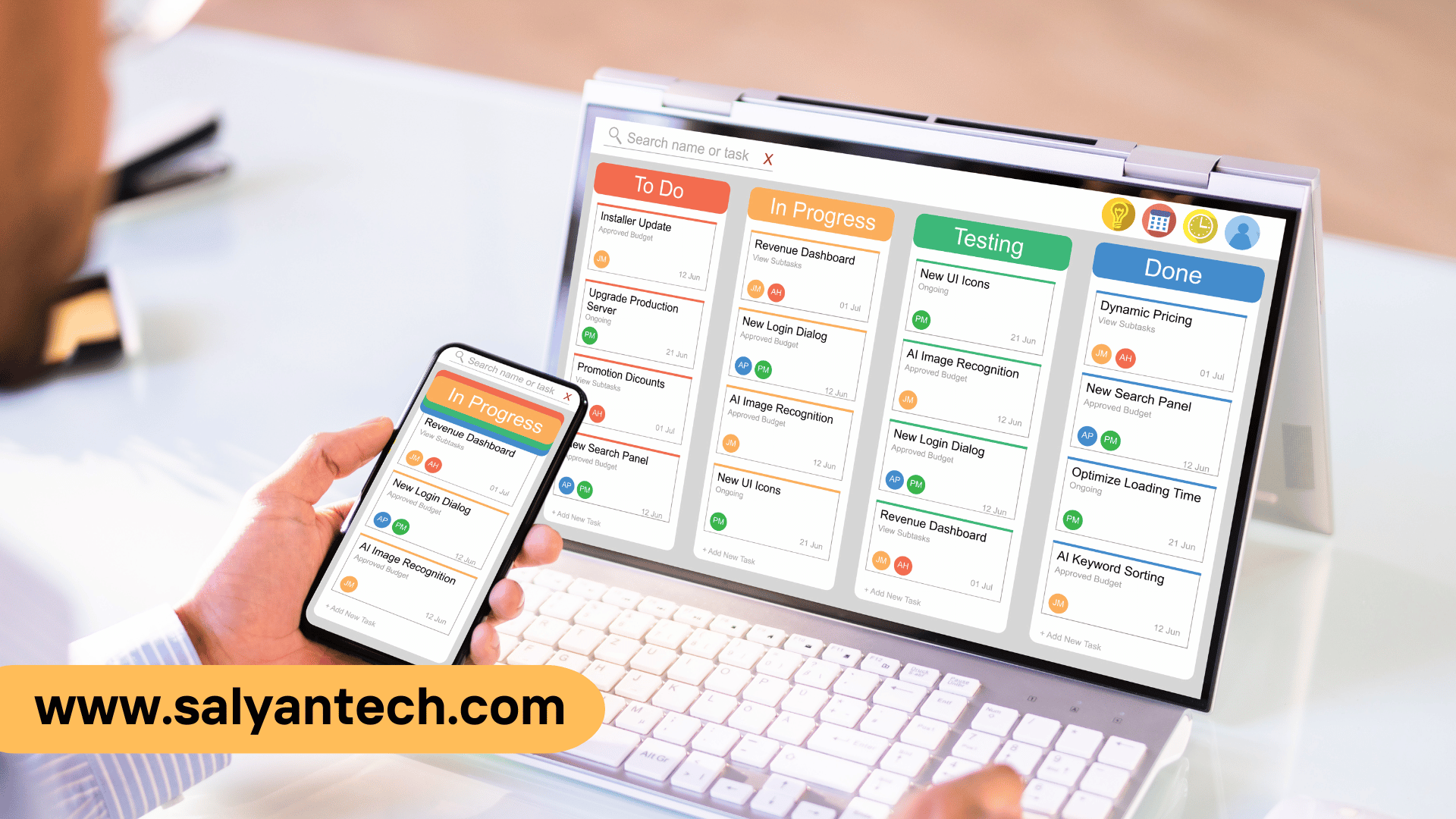

Enter online bom management software – a game-changer for businesses looking to streamline operations and enhance accuracy. This modern solution transforms how companies handle their BOMs, offering a suite of tools designed to keep everything organized, updated, and accessible from anywhere.

Let’s explore how this innovative tool can elevate your manufacturing game.

[Source: Unsplash]

8 Perks of Online BOM Management Software

BOM management software brings a host of advantages that can significantly improve the efficiency and accuracy of your manufacturing processes. Here, we’ll explore some of the key benefits that make this technology a must-have for modern businesses.

Centralized Data

Online BOM management software provides a centralized repository for all your BOM information. Every component, material, and sub-assembly detail is stored in a unified system.

With centralized data, there’s no more scrambling through multiple spreadsheets or documents to find what you need. This saves time and ensures that everyone in your organization has access to the most up-to-date information, reducing the risk of errors and miscommunication.

Real-Time Updates

When you use online BOM management software, any changes to the BOM are instantly reflected across the system. This feature is particularly beneficial for dynamic environments where changes to components or specifications are frequent.

Real-time updates ensure that everyone involved in the production process, from engineers to procurement teams, works with the latest information, thus minimizing the likelihood of costly mistakes.

Improved Collaboration

A platform where team members can access and update BOM information simultaneously, regardless of their physical location, is a massive boost to productivity. This is particularly advantageous for companies with remote teams or multiple locations.

All this leads to better communication and decision-making, as all team members can access the same up-to-date information and contribute their expertise.

Cost Efficiency

As I’m sure you know, managing costs is a critical aspect of manufacturing. This software enables companies to identify potential savings and make more informed financial decisions by providing detailed cost breakdowns and allowing for real-time cost tracking.

Additionally, the reduction in errors and improvements in efficiency brought about by BOM management software can lead to significant cost savings over time.

Compliance and Traceability

BOM management software ensures that all components and materials used in production meet regulatory standards. It provides a clear audit trail for each BOM, documenting every change and update.

Traceability is invaluable during audits or quality control checks, allowing companies to quickly and easily demonstrate compliance with industry standards. Moreover, having a detailed record of all BOM changes helps in identifying and addressing any issues that may arise

Automation

Automation is a standout feature of online BOM management software. It takes over repetitive tasks like data entry and updating BOMs, which are traditionally prone to human error. This shift from manual to automated tasks minimizes errors and frees up valuable time for your team to focus on more strategic activities.

Seamless Integration

Online BOM management software seamlessly integrates with key enterprise systems, such as ERP (Enterprise Resource Planning), MRP (Material Requirements Planning), PLM (Product Lifecycle Management), and CAD (Computer-Aided Design) software.

This ensures that BOM data is consistently and accurately shared across all platforms, eliminating the need for manual data entry.

Robust Version Control

Managing different versions of BOMs can be challenging, especially in complex manufacturing environments where changes are frequent.

Robust version control allows users to track and manage multiple BOM versions efficiently. It ensures that the most recent version is always accessible while maintaining a comprehensive history of all changes.

Version control is crucial for preventing mistakes that can arise from using outdated information and provides a clear audit trail for quality control and compliance purposes.

Conclusion

The true magic of online BOM management software lies in its ability to adapt and grow with your business. Imagine a future where your production lines are never stalled due to miscommunication or outdated information, where your teams are always in sync, no matter where they are, and where every decision is backed by accurate, real-time data.

Automation eliminates the drudgery of repetitive tasks, allowing your team to focus on innovation and improvement. Seamless integration with other systems ensures a harmonious flow of information across all departments, while robust version control keeps everyone on the same page, maintaining a clear history of changes and updates.

Can your business afford not to embrace the power of online BOM management software? The benefits are clear, the technology is accessible, and the impact on your bottom line and operational efficiency can be profound.

Read Also: How Investing in Mutual Funds via App Helps You Earn 1% More?